Views: 0 Author: Site Editor Publish Time: 2025-10-09 Origin: Site

The bread production line is the core system for modern bakeries to achieve batch, stable, and efficient production. From dough formulation and mixing to shaping, proofing, baking, cooling, slicing, and packaging, each process stage impacts the quality of the finished product and production efficiency. A rationally designed production line not only ensures consistency in the texture and appearance of the bread but also reduces labor costs, minimizes food safety risks, and improves the pass rate through automation.

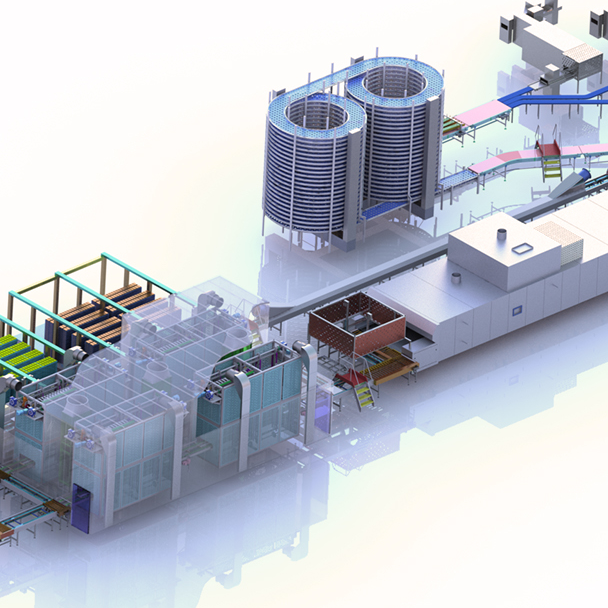

A typical bread production line consists of core units such as mixers, dough divider and rounding machines, shaping machines, continuous or intermittent proofing chambers, tunnel/rotary ovens, cooling conveyors, slicing and packaging equipment, and manufacturers usually configure these components in a modular manner to meet varying production capacity and product type requirements.

In terms of process design, the shaping method and rhythm should be determined based on the product type. For frozen processes or soft doughs, it is recommended to adopt a more precise temperature-controlled proofing system and low-vibration conveying to minimize bread deformation and the generation of crumbs; the selection of ovens directly affects the performance in terms of browning, puffing, and energy consumption.

From an investment and operational perspective, selection should balance daily production capacity, product category flexibility, workshop layout, and energy consumption budget. For export or branded production, attention should also be paid to the equipment's energy efficiency ratio, degree of automation, as well as the supplier's after-sales response and training capabilities; trial production and sample verification are also important steps to avoid risks in large-scale production.

As a mature equipment manufacturer, AOCNO provides customized solutions ranging from single machines to complete production lines. It possesses a rich array of modular products in key processes such as proofing cabinets, ovens, and slicing and packaging. These products can be configured and supported with trial production according to the customer's production capacity and product portfolio.

Conclusion: A well-designed bread production line that prioritizes automation and hygiene can significantly enhance productivity and reduce operational costs while ensuring consistency in taste and appearance. AOCNO offers professional consulting, customized design, and technical support. Welcome to contact us.

How Do You Choose the Right Bread Production Line for Your Bakery Factory?

Which Bread Former to Choose? Toast vs Hamburger Production Lines

High-Efficiency Bread Production Line | Bakery Equipment Manufacturer

Customized Bread Production Line Manufacturer | AOCNO Bakery Line Expert

Bread Slicer Machine Applications and Benefits in Bakery Production Lines

Cooling and Freezing Towers in Bakery Production:Key to Freshness and Efficiency

Bread Molding Machines: Models, Capacity, and Automation Guide

The 'heart' of the bread production line - dough mixer selection and application guide

Address: North Of Weier Road,East Of Jingwu Road,East Zone,Anping county,Hebei Province,China

Whatsapp/Wechat: 0086 15127880005

E-Mail: info@aocno.com